>> Product Description

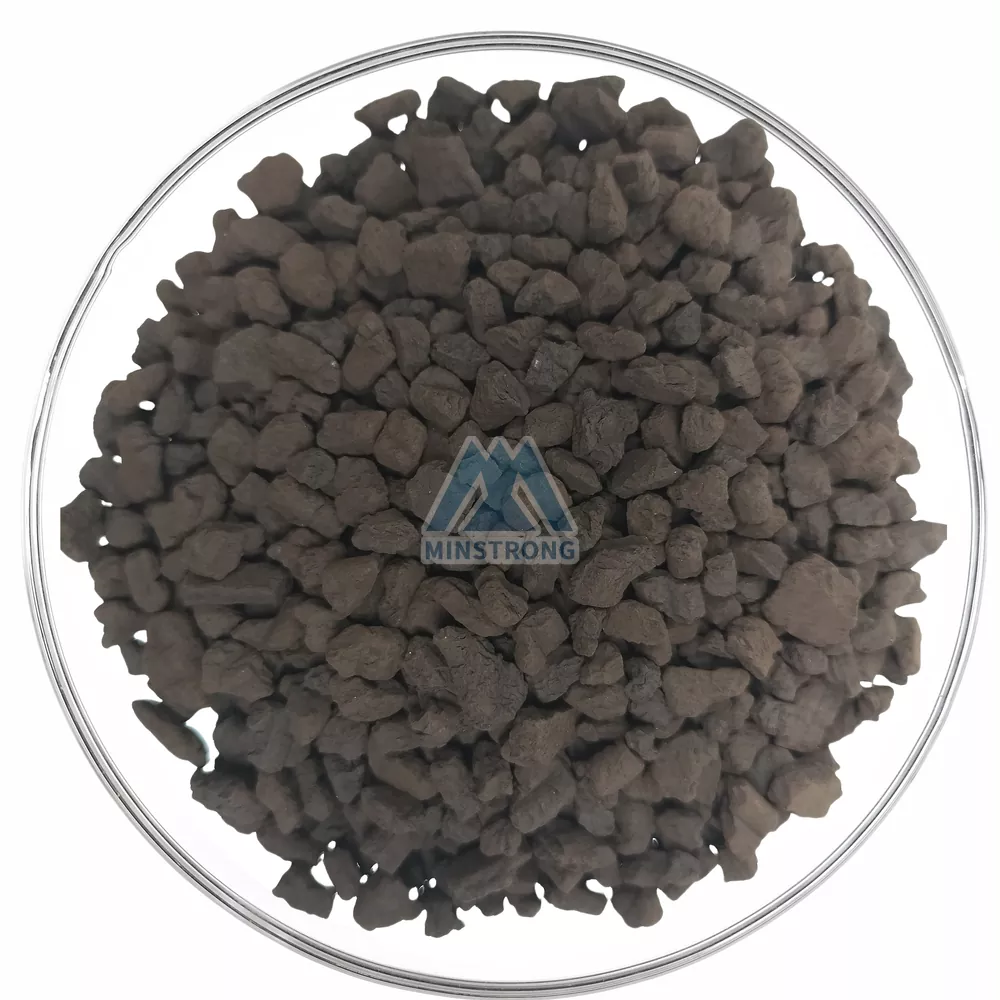

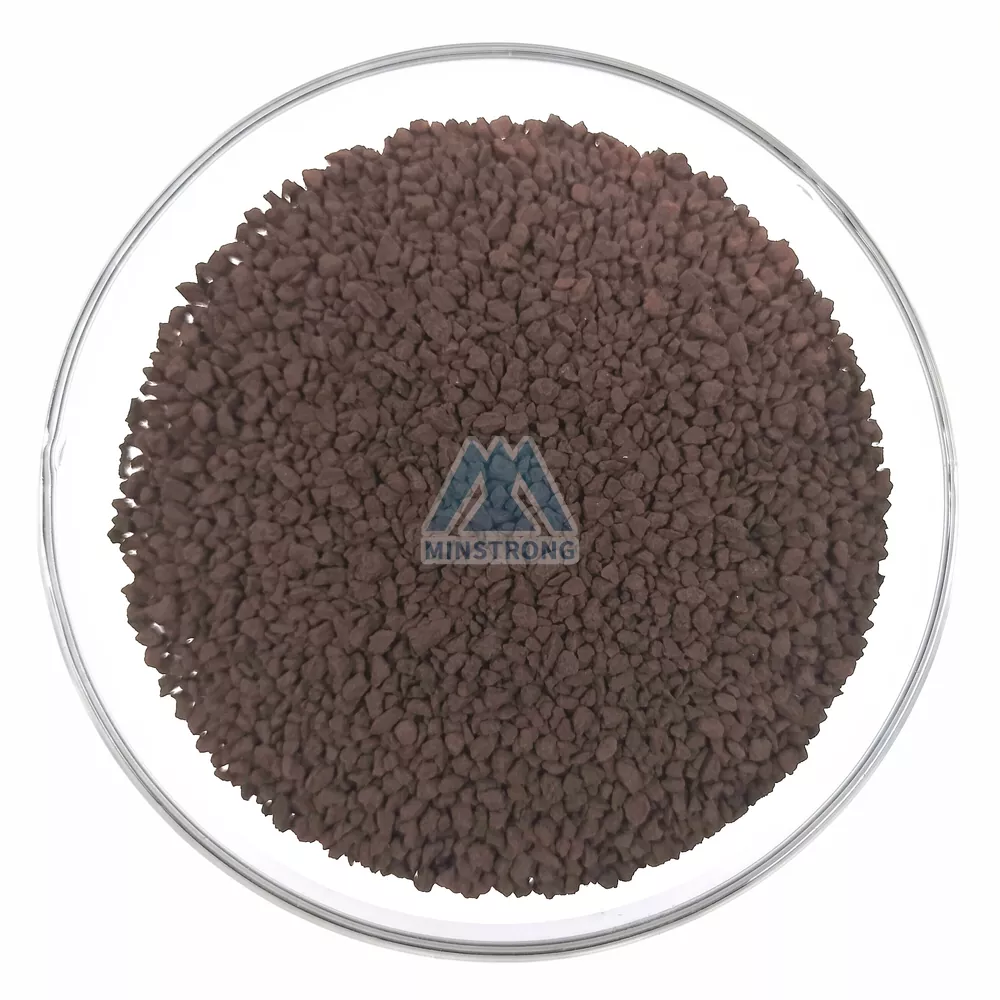

Carbon Monoxide Catalyst (MINSLITE-A)

Minstrong granular carbon monoxide catalyst(MINSLITE-A) can convert carbon monoxide into carbon dioxide at low temperature, avoiding equipment and personnel from being damaged by carbon monoxide.

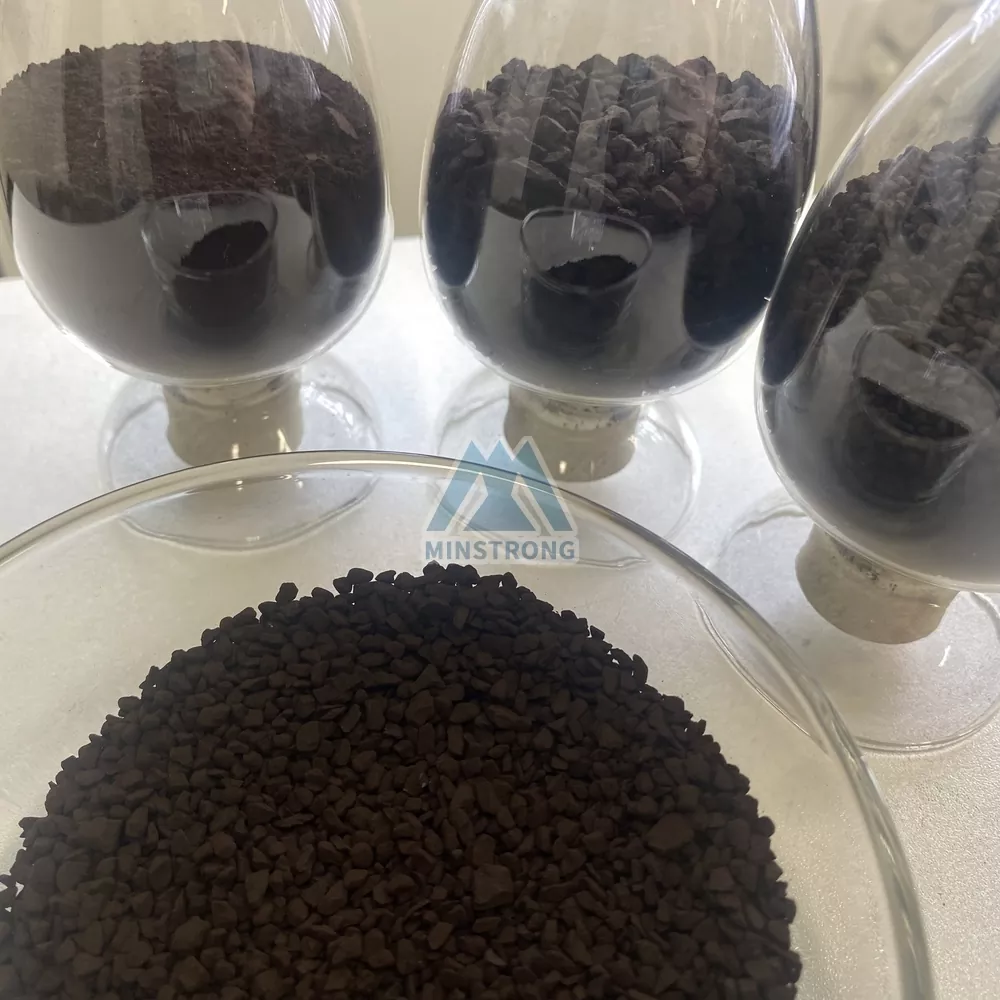

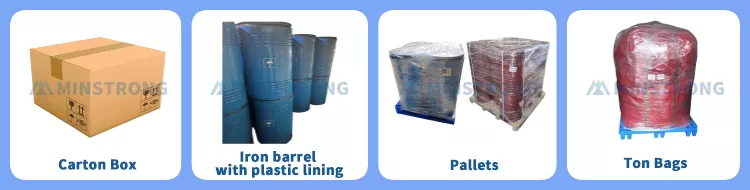

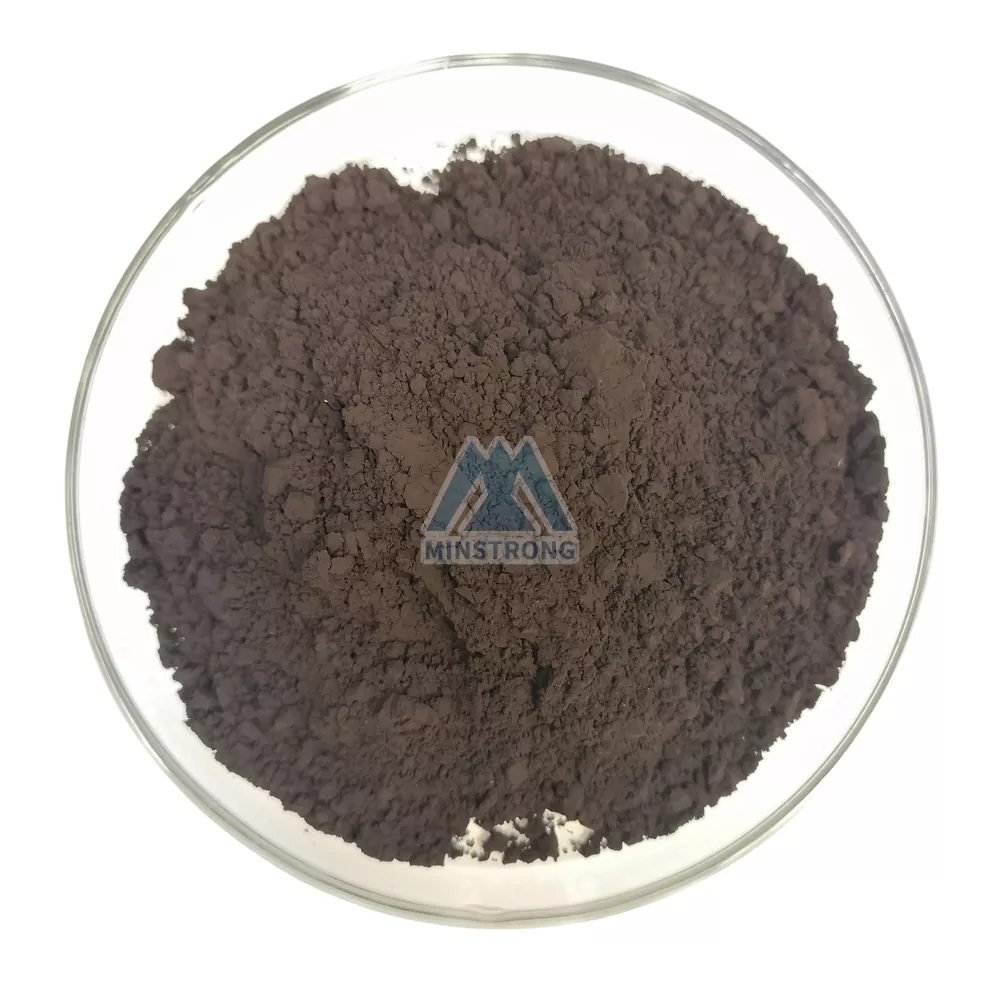

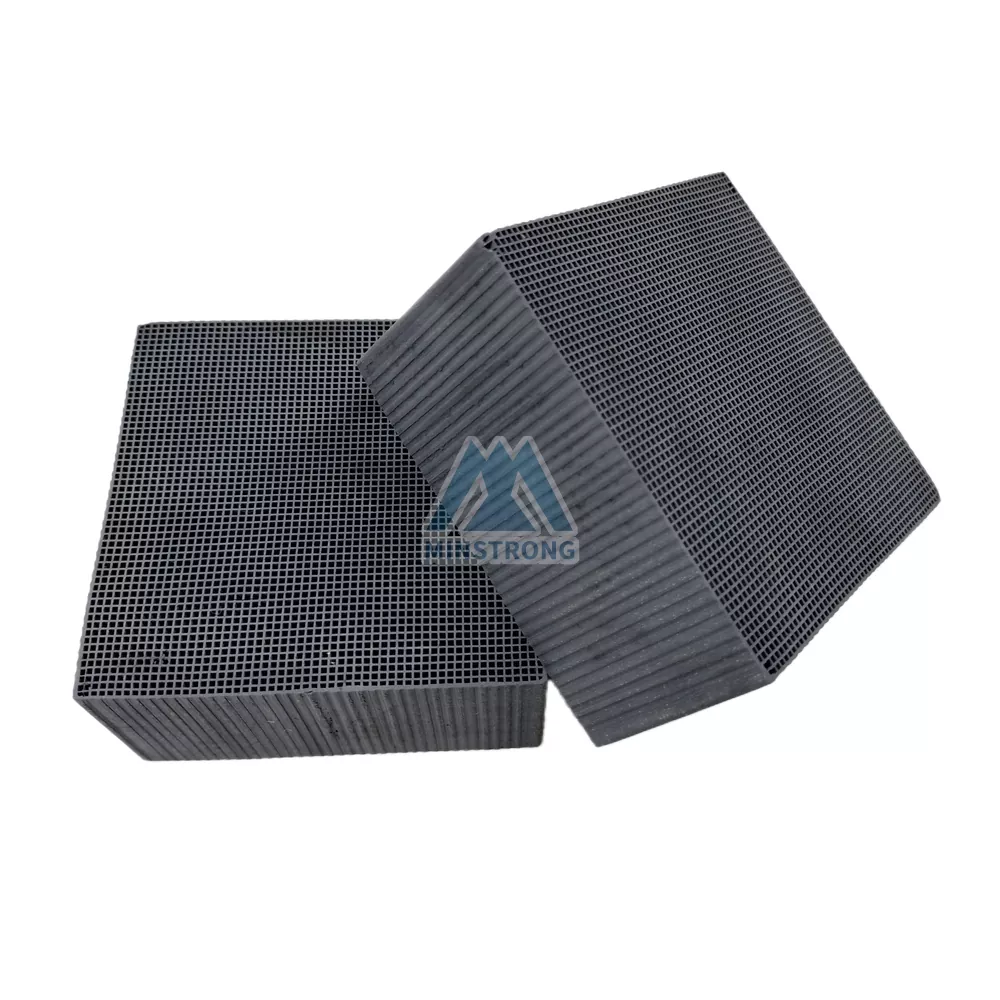

Minstrong provides catalysts in various specifications to suit different working conditions and applications. Catalyst powder allow you to use them directly or process them into other forms of catalysts, such as honeycombs or filters.

Carbon monoxide catalyst(MINSLITE-A) are all made of metal oxides, do not contain any flammable or volatile substances, are safe to use, and can withstand high temperatures.

The advantages of granular carbon monoxide catalysts are very good performance and strength, with the highest active ingredient content (100%). This product is aimed at high-standard projects and can achieve goals that general catalysts cannot achieve.

The granular carbon monoxide catalyst is composed entirely of active ingredients, can work stably under extreme working conditions, and has a longer service life.

In fact, in most countries, our customers use more granular carbon monoxide catalysts, especially in large projects with extreme working conditions and strict requirements, which can bring extremely high customer satisfaction. For projects that want to achieve their goals perfectly, we recommend the use of granular carbon monoxide catalysts.

>> Product Parameter

| Minstrong Granular Carbon Monoxide Catalyst(MINSLITE-A) Technical Data | |

|---|---|

| Type |

4-8mesh, 6-12mesh, 8-14mesh, 10-16mesh, 12-20mesh (Other sizes can be customized) |

| Active Effective Constituent | 100% |

| Abrasion Strength | ≥95% |

| Specific Surface Area | 160-240 m2/g |

| Density | 0.75-1.0 g/ml |

| Adaptable Temperature | ≤500 ℃ |

| Space Velocity | 1000-20000 /h |

| CO removal ability per Hour | ≥ 100.0 mg/g |

| CO Removal efficiency | >99.9% |

| Catalyst customization | available |

| Size Specification Available | |

|---|---|

| Type | Description |

| MINSLITE-AG01 | 4-8 mesh |

| MINSLITE-AG02 | 6-12 mesh |

| MINSLITE-AG03 | 8-14 mesh |

| MINSLITE-AG04 | 10-16 mesh |

| MINSLITE-AG05 | 12-20 mesh |

| Note: Catalyst specification parameters can be customized according to requirements. | |

If you don't find specifications you want

The above data are the specifications that Minstrong produces on a daily basis. We have a large inventory, and our products are continuously upgraded and expanded.

If you need other specifications, you can contact Minstrong Customization is available.

If you don't know which type of catalyst to choose, you can contact Minstrong to help you choose the most suitable model and size.

>> Product Application

- Fire mask / Gas mask & Refuge chamber: CO removal catalyst can be put into the filter layer of the gas mask or the gas scrubber of refuge chambers,so as to convert CO into CO2, to ensure the safety of personnel.

- High purity gas treatment : In the production of high purity gases such as N2 and O2, a small amount of CO is produced, and carbon monoxide catalyst (CO removal catalyst) can remove CO at low temperature.

- Compressed air breathing equipment: Such as diving equipment, medical compressed breathing air, oxygen systems, converting CO into CO2.

- Compression systems and air separation systems: Convert CO in compressed gas into CO2 at low temperatures.

- Raw materials of catalyst: Used to produce various catalysts for purifying carbon monoxide.

- Coating material: As a coating for carriers such as ceramic honeycombs, make it has the function of eliminating CO.

- Instruments and laboratories: Purify the instrument's detection gas, adjust the zero point, and eliminate the interference of CO.

- Removal of carbon monoxide in the absence of oxygen: Removal of carbon monoxide from inert gases such as nitrogen, argon, helium, etc.

Minstrong Technology Co., Ltd

Minstrong Technology Co., Ltd

WeChat

Scan the QR Code with wechat